Characterization of Flow regimes in T-Junction Microfluidic Devices

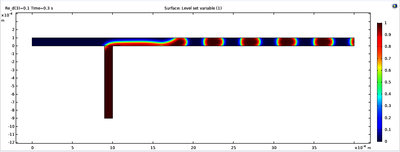

In this work, finite element method (FEM) based commercial software COMSOL Multiphysics® has been used to perform two-dimensional simulation of droplet formation inside T-junction microchannel. The laminar two-phase flow, level set module modules of

COMSOL Multiphysics®

with free triangular meshing and time dependent PARDISO solver has been used to defined the physical problem. This work have focused on investigation of different flow regimes of droplet formation in the channel by varying the flow governing parameters. The primary source of our motivation is the lack of a rigorous parameter based study investigating the parameter brackets required to observe proper monodispersed droplet formation in the channel. The mapping of the droplet effective diameter and droplet breakup time with Capillary Number (Ca) accounting the interfacial tension in the range as 0.005N/m to 0.01N/m, continuous phase Reynolds number (0.001c<0.1) and dispersed phase Reynolds number (0.001d<10) has been developed as an outcome of this work. The results show that the effective droplet diameter decreases with increase in surface tension, under otherwise identical conditions. It is further observed that the frequency of monodisperse droplet formation enhances with increasing Rec, keeping rest of the parameters fixed. However, the effective droplet diameter also increases with increasing Red values. Our results can have potential use for obtaining specific droplet diameter size for improving biological assay preparation and cell sorting, as well as in the designing of microfluidic devices, where an evident need of controlled droplet size.