Flow and Heat Transfer Through an Open Cell Metal Foam

Metal foams are interesting materials with many potential uses. They are characterized by a cellular structure represented by a metal (or a metal alloy) and gas voids inside. A common metallic cellular material is a solid sponge, also known as open cell metal foam. Due to their intrinsic high porosity and large specific surface area [1], these materials are considered to have very promising properties to improve efficiency and minimize the required weight and volume of novel industrial heat exchangers. In that case, the complexity of the convective heat transfer process and the number of parameters to analyse simultaneously, demand a preliminary and hugely wide experimental activity to design foamed components with a good quality for energy transferring systems. The development of computational models could help to reduce experimental works and costs, although the task is very challenging. Numerical studies modelling porous media has been used to capture the details of the intricate sponge structure while considering the porous solid-fluid systems as homogeneous, as remarked in [2]. Moreover, computational attempts modelling representative elementary volume (REV) of a sponge with its solid and void phases, have also shown encouraging results [1,2].

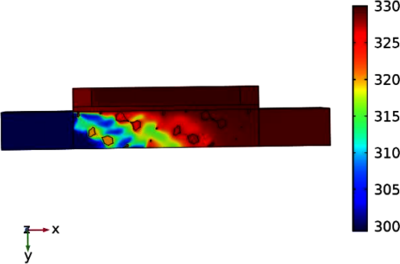

In this work we use COMSOL Multiphysics® 5.4 to model the fluid flow and heat transfer process through a three dimensional open cell aluminium foam of a heat exchanger. In the device, the heat is transferred from a stream of hot water to a cold air flow, by convection and diffusive mechanisms in the fluids, while heat conduction is set in the solid regions of the system. We start our modelling work by generating the geometry of the metal sponge in SolidWorks® and importing the resulting CAD into COMSOL Multiphysics® by using the capabilities of the CAD Import Module. The compressible air flow through the connected voids of the sponge and the water flow are both assumed as laminar and are coupled to the heat transfer mechanisms by using the Conjugate Heat Transfer physics from the Heat Transfer module, also complemented by the CFD module.

The numerical findings of the simulations show that the computational model developed with COMSOL Multiphysics® is effective for modelling the conjugate heat transfer process through the three dimensional open cell aluminium foam. Furthermore, the computational results prove that the energy transfer of the exchanger is enhanced taking advantage of the material's high porosity and large specific surface area.

[1] S. Meinicke, T. Wetzel and B. Dietrich, CFD modelling of single-phase hydrodynamics and heat transfer in solid sponges, 11th International Conference on CFD in the Minerals and Process Industries, 7-9 December 2015, CSIRO, Melbourne (Australia).

[2] A. Kopanidis, A. Theodorakakos, E. Gavaises and D. Bouris, 3D numerical simulation of flow and conjugate heat transfer through a pore scale model of high porosity open cell metal foam, International Journal of Heat and Mass Transfer, 53, 2539-2550, (2010).