From the Laser Parameters to the Tribological Properties with COMSOL Multiphysics®

Whereas the physic models of fluid lubrication should be able to provide quantitative predictions to industrial problems, it is somehow demanding to provide the input data to feed these high-level equation systems. The operating conditions are generally available, and the material properties can be obtained through thorough and costly independent measurements. However, the surface topography characterization required in some cases comes with its own challenges.

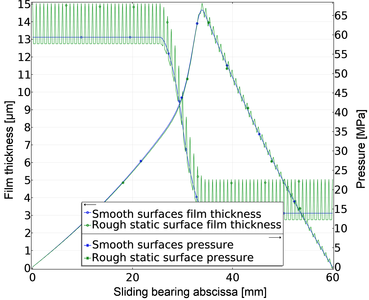

In this work, the authors compare two different approaches to obtain the topography of laser texturation. Their aim is to demonstrate their strengths and weaknesses when being used as input data in a fluid lubrication model able to take into account non smooth surfaces. The first method consists in including the height distribution stemming from topography measurements. The second is rather different and deals with the numerical predictions of the topography. Indeed, SIMTEC has developed a thermo-hydraulic model to quantitatively predict the shape of the laser crater. The output of such a model is a prediction of the topography.

The lubrication results obtained with the numerical predictions are presented, together with the strengths and difficulties of both methods. Whereas the experimental data may seem more easily available to the lubrication model developers, they actually require the making of a prototype surface. For its part, the numerical data provided by a thermo-hydraulic model may be different from the topography measurement. However, for the owners of such a model, the topography is available at a very early stage of the project. Moreover, it is possible to test a large among of laser operating conditions and directly evaluate their influence on the contact behaviour through the different surface shape they generate.