Numerical Simulation of Air Permeability Coefficient of 3D Textile Layer

In recent decades, 3D fabrics are being increasingly used in aerospace, military, protection, sports and leisure and other industrial applications. 3D textile structures are formed from two fabric layers (top and bottom layer) combined by a spacer yarn or connecting layer. The computational analysis of 3D textile materials allows to predict heat and mass transfer properties such as the effective heat transfer, heat capacity, water vapor transmission, air permeability coefficients, which influence the wearing comfort of the clothes [1, 2].

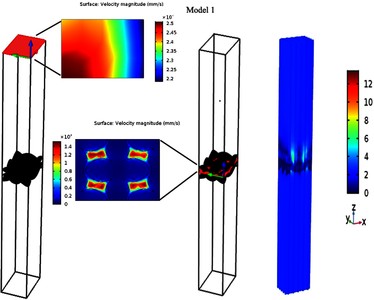

This study focuses on air permeability coefficient. Air permeability is defined as fabrics resistance to the air flow at a given differential pressure. It has a huge impact for processes of heat exchange (vapor and moisture transport, thermal properties) which occurs between human skin and textiles [3]. In this work we present 3D steady state computational models to predict air permeability coefficient in micro and macro scales. The simulations were created with the Laminar Flow (spf), Free and Porous media flow (fp) interfaces within COMSOL Multiphysics® . As boundary conditions, the inlet pressure was set to 200 Pa (according to the ISO 9237:1995 test standard), the outlet pressure was set to 0 Pa (that corresponds atmospheric pressure). A symmetry condition was set at the side walls.

[1] R. Barauskas, A. Abraitienė. A Model for Numerical Simulation of Heat and Water Vapor Exchange in Multilayer Textile Packages With three-dimensional Spacer Fabrics Ventilation Layer. Textile Research Journal 0(00) 1–21, 2010

[2] G. Ertekin, A., Marmarali. Heat, air and water vapor transfer properties of circular knitted spacer fabrics. Article in Tekstil ve Konfeksiyon , 2011

[3] A. Pezzin. Thermo-physiological comfort modelling of fabrics and garments. PhD thesis. (2015)

Download

- AG_Cambridge_2019_Poster.pptx - 0.43MB