Simulation of an Explosive Resistant Flywheel Energy Storage Device Based on a Steel Strip Spiral

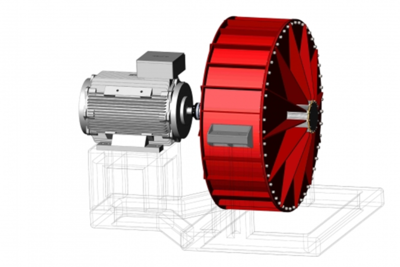

Sustainable energy storage is essential for a successful energy transition towards renewable energies. Advanced future power grids will consist almost exclusively of instable and variable sources like solar and wind power. However, fluctuations are very problematic for the power grids, as they are destabilizing the frequency. Therefore, regulating components such as energy storages must be integrated into the grids. Standard electrochemical storages like lithium-ion batteries are expensive, ecologically problematic and have a short lifetime based on their charging or discharging cycle. One efficient way to stabilize the frequency of a power grid is by means of flywheels. Current, flywheels are made of bulk material or carbon fiber reinforced plastic (CFRP) discs. However, the large-scale use of state-of-the-art flywheels are slowed down due to the safety requirements. In case of a defect the energy stored in the flywheel will be released explosively. To overcome these safety issues, an innovative new kind of flywheel is presented. The flywheel consists of a glued thin spiral steel strip with a thickness of about a quarter of a millimeter, which is coiled up on an aluminum core and centered by a shaft. In case of material failure, the steel strip spiral unreels and disintegrates which results in a smooth transition of the stored kinetic energy. Thus, the explosively is defused. The simulation software COMSOL Multiphysics® was used to create a numerical model of the novel flywheel energy storage (FES) device based on a steel strip spiral by means of the finite element method (FEM). The model is set up parameterized to represent a large number of design possibilities. These parameters are material parameters (Young's modulus and Poisson's ratio of steel as well as adhesive) and geometry parameters (number of turns, inner and outer diameters, and aspect ratio of steel and adhesive). The model is statically, frequency-dependently, and time-dependently solvable. The flywheel consists of up to 2,000 turns, which poses a great challenge for the creation of a numerical model due to a high aspect ratio. The complete setup is generated by a Java® method using the so-called "Application Programming Interface", since a manual selection is no longer practicable due to a high number of domains. The model is implemented as 2D as well as 3D-geometry and the adhesive is explicitly represented as a domain. The Structure Mechanics Module was used to simulate the deformation of the flywheel under rotation up to 5500 rpm. In addition, the frequency response was investigated, and the study was finalized by a contact model to see the effect of an adhesive detachment. The mechanical behavior of the flywheel was investigated. The frequency response analyses have determined the resonate frequencies which are critical during the operation. Six critical frequencies in the range of about 30 Hz to 90 Hz were identified. The contact model reveals that the detachment of the adhesive in only one spiral arm results in a complete breakdown of the structure. Hence, critical operational parameters of the flywheel are revealed, which is a major step toward reliable industrial development. Experimental work is in progress to verify these numerical results.