Strong performance is a key focal point in designing any electronic device. In an effort to extend the design space for further applications and to take steps toward realizing the Internet of Things, the desire for high performance is now paired with an interest in achieving greater physical flexibility — a change from today’s rigid and brittle electronic devices. See how stretchable electronics are successfully blending strength and flexibility to offer new opportunities for technological growth.

The Internet of Things Inspires a New Wave of Electronics

You may already be familiar with the buzz surrounding a phenomenon known as the Internet of Things, or IoT. The idea behind IoT is to create a network of physical objects that gather and communicate information with one another, enabling further “smart” technology that functions without the need for user input. As a previous blog post discusses, optimizing the design of modern electronics is an important step to make all of this possible.

The path toward the Internet of Things requires further optimizing the design of electronics.

Over the years, we have seen the power and speed of electronic devices evolve, but in most cases the designs themselves have remained breakable and inflexible. Such properties can be attributed to a material that is at the heart of electronics: wafers. Wafers are thin slices of a semiconductor material, usually silicon, that serve as a substrate for microelectronic devices.

A closer look at a wafer, one of the key components in many electronic designs. Image by Santi — Own work. Licensed under CC BY 2.0, via Flickr Creative Commons.

While the electrical properties of wafer-based technologies are favorable, these devices lack the ability to stretch or bend without cracking. Stretchable electronics, as we’ll discuss next, are changing the scope of such design properties, fostering potential technological advancements along the way.

The Underlying Dynamics of Stretchable Electronics

When it comes to designing stretchable electronics, there are a couple of different paths that can be taken. The first approach involves depositing stretchable electronic devices and circuits onto a stretchable substrate. The alternate approach involves fully embedding these types of devices and circuits within a stretchable material. In both cases, polymers are typically selected as the substrate or material, respectively.

So what happens when a rigid component is deposited onto a stretchable substrate? Whenever the substrate is flexed, the interconnects of the structure undergo an increased mechanical strain. This is due to the fact that upon bending the substrate, the relative spacing of each interconnect increases at an equal rate to that of the increasing length of the substrate. The result is a conformable electronic system that can retain its full functionality as it undergoes stretching or bending.

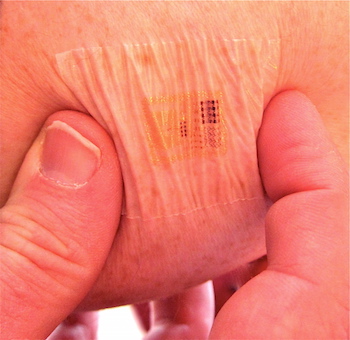

This patch, an example of a stretchable electronic, provides measurements of a person’s electrical activity. Image by Steve Jurvetson — Own work. Licensed under CC BY 2.0, via Flickr Creative Commons.

Let’s take a closer look at some of the innovative designs that stretchable electronics are helping bring to life.

Stretchable Electronics Help Innovative Designs Take Shape

To address the growing concerns behind sun exposure as well as to educate consumers, L’Oréal has designed a wearable patch that monitors UV exposure. The transparent patch, which is about one square inch (~6 cm2) in size and half the thickness of a typical strand of hair, contains photosensitive dyes that change color upon exposure to UV rays. After taking a photo of their patch, users can upload the image to a mobile app that analyzes their results. The stretchable electronic device — an intersection between the technology and beauty industries — accounts for skin tone in its analysis and can be applied to any part of the skin that the user wishes to monitor.

Along with the beauty industry, stretchable electronics are also making their mark within the healthcare setting. MC10 has developed an adhesive tracking sensor that offers access to a person’s health parameters. Even though it has the look and feel of an adhesive bandage, the sensor features a number of miniaturized technologies designed for tracking and monitoring. The accelerometer and gyroscope help track motion, while a series of sensors monitor vital signs like muscle performance and heart activity. An added bonus is the sensor’s rechargeable battery. This stretchable electronic helps to paint a clearer picture of a patient’s day-to-day health with both accuracy and speed, ensuring that the proper healthcare steps are promptly taken.

What technology will stretchable electronics shape next? The answer to this is up to engineers.

Learn More About Stretchable Electronics and Related Technology

- For more details on the stretchable electronic designs highlighted here, read this IEEE Spectrum article

- Interested in learning more about the Internet of Things? We encourage you to check out these blog posts:

- Read a related blog post: Design Safe Wearable Technology with Heat Transfer Modeling

Comments (0)