Uncertainty Quantification and Propagation in Multiphysics Modeling of the PVT Growth of SiC Crystal

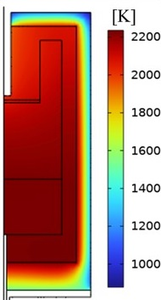

The wide bandgap semiconductor silicon carbide (SiC) has drawn increasing attention in recent years as a promising material for high-power, high-frequency, and high-temperature operating devices. These outstanding properties of SiC make it a good candidate to replace silicon in many applications [1-2]. One of the most common methods for growing high-quality SiC crystals is through the physical vapor transport (PVT) method. The PVT method, also known as the modified Lely method was introduced by Tairov and Tsvetkov[3]. Using this method, scientists were able to grow one large crystal of a single polytope by careful control of the pressure and temperature. In the PVT method, the furnace is heated by induction coils. At a high temperature, the SiC powder source sublimes to various vapor species (Si, C, Si2C, SiC2, and SiC). The temperature gradient between the source material and the seed is the driving force for the transport of vapor species from the source surface to the seed surface in the reactor. Subsequently, the transported vapor species recrystallize on the seed, contributing to bulk crystal growth. Although the physical vapor transport (PVT) method has been widely used to produce SiC bulk crystals, there are still some unresolved problems. In addition, the process is conducted at very high temperatures in a quasi-closed graphite crucible, the furnace acts like a “black box” as there is no access for taking measurements or observing the changes during the process. Therefore, numerical modeling can provide a further understanding of the physicochemical behaviors of the crystal growth system and accelerate process optimization for SiC bulk crystal growth. However, the uncertainties in these computational models could affect the accuracy of the predicted results. Therefore, uncertainty quantification and propagation is a crucial technique for evaluating the precision of model predictions and enhancing the robustness of the model. In this study, COMSOL Multiphysics® was used to investigate the induction heat transfer, mass transport, powder source sublimation, porosity evolution and crystal growth in a PVT furnace. The current work is a coupling of the AC/DC Module, the Heat Transfer Module and the Chemical Species Transport interfaces in COMSOL®. Different radiation models are applied to examine the effects of radiation on the temperature distribution in the furnace. Powder porosity evolution during the process is predicted based on vapor transport mechanism. To describe the growth process, a physical growth model is employed in addition to the chemical reaction, mass transport of vapor species, and kinetics of decomposition and deposition. Based on the developments in Ref. [4] we evaluate activities of silicon and carbon with a coupled multi-physics approach which integrates atomistic calculations of non-stoichiometric SiC crystals. Finally, due to the uncertainty of the thermos-physical material properties and various input parameters, a thorough uncertainty quantification and propagation analysis is conducted to quantify the uncertainty associated with numerical model input parameters.

Download

- Ramadan_5811_presentation.pdf - 0.98MB