Impact of Operating Parameters on Precursor Separation in "Air Hockey" Spatial Atomic Layer Deposition Reactor

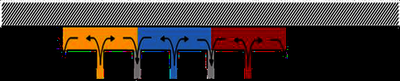

A defining characteristic of atomic layer deposition (ALD) is the sequential exposure of a surface to self-limiting, saturating reactions. Temporal ALD operates through intermittent purge cycles, while spatial ALD relies on physical separation accomplished by delivering reactants through a deposition head located in close proximity to the substrate’s surface. An inert gas stream placed between precursors acts as a diffusional barrier to prevent mixing. A dysfunctional barrier results in gas phase reaction and non-ALD growth. To understand the impact system parameters have on the efficiency of the gas barrier, this work presents a study of the fluid dynamics and concentration diffusion for the system using COMSOL Multiphysics® simulation software.

We present a case study for ALD of alumina by trimethylaluminum (TMA) and water using a novel spatial ALD system analogous to an air hockey table. In contrast to other spatial ALD reactors that are limited by mechanical constraints, dispersed nitrogen inlets float a substrate overtop an injector region to deposit films within a deposition gap of less than 100 μm. The flotation height, or deposition gap, is a function of the fluid pressure underneath the substrate. An accurate height estimation from the parameters is necessary to evaluate the efficiency of the gas barrier. In-situ height measurements are used to validate the COMSOL Multiphysics® model, and the results are in good agreement for different operating conditions.

This COMSOL Multiphysics® model takes an inverse approach to provide an accurate flotation height calculation. The deposition gap is critical in defining the fluid domain; thus, the initial flow conditions are solved after the deposition gap has been specified. A force balance between the fluid pressure and the substrate is implemented into the model through a global equation node in the Laminar Flow interface. Once the Laminar Flow interface is complete, the diffusion of the precursor species is calculated. This work investigates how diffusivity, deposition gap, inert flow rate, and geometric design influence the effectiveness of precursor separation by evaluating the concentration of the precursors at the substrate surface. Small deposition gaps prevent precursor intermixing; however, the diffusional barrier is not effective when the inert flow rate is low. Specifically, high diffusivity enables the precursors to readily diffuse beyond their ideal zone, cause gas phase reactions, and lead to CVD growth. Additionally, the uniform surface exposure of reactant is altered, leading to non-uniform growth at the edges of the deposition area. Successful precursor separation can be achieved at large flotation heights when the inert flow is large; however, the precursor concentration at the surface becomes low. These conditions may lead to insufficient saturation of the surface and non-ideal ALD growth. Additionally, the geometric design of the reactor plays a critical role in preventing precursor intermixing.

Download

- grasso_poster.pdf - 1.62MB

- grasso_cfdtransport_presentation.pdf - 1.86MB